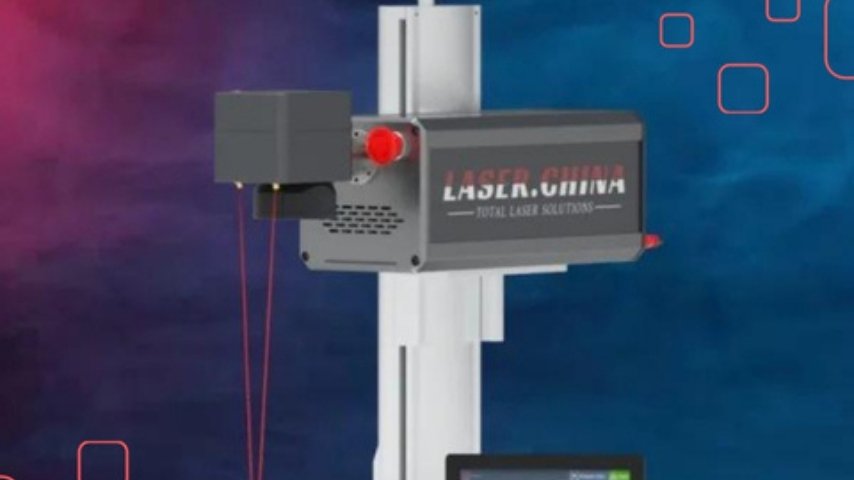

Laser rust removers have emerged as innovative solutions for tackling rust and corrosion on metal surfaces. These machines utilize concentrated laser beams to eliminate rust and other contaminants, providing a highly effective and environmentally friendly alternative to traditional rust removal methods. Understanding how laser rust removers work and their benefits can help businesses improve their maintenance processes and overall operational efficiency.

1. How Laser Rust Removers Work

A laser rust remover operates by directing a high-intensity laser beam at a rusted surface. The process involves several steps:

- Laser Emission: The laser system generates a beam of light, typically using solid-state or fiber laser technology. The power of the laser can vary, often ranging from 100 to 1000 watts or more, depending on the application and the thickness of the rust.

- Absorption and Vaporization: When the laser beam hits the rusted surface, the energy is absorbed by the rust. This absorption causes the rust to heat up rapidly, leading to thermal expansion. As the rust expands, it becomes brittle and disintegrates, either vaporizing or flaking away from the underlying metal surface.

- Control and Precision: Operators can adjust various parameters, including laser intensity, speed, and pulse duration, allowing for precise control over the cleaning process. This adaptability enables the removal of different types of rust and contaminants without damaging the base material underneath.

- Safety Considerations: Laser rust removers come equipped with safety features such as protective enclosures, fume extraction systems, and safety goggles for operators to minimize exposure to laser radiation and harmful fumes produced during the rust removal process.

2. Advantages of Laser Rust Removers

Laser rust removers offer a range of benefits that make them an attractive option for industries dealing with rust and corrosion:

- Effectiveness: Laser cleaning is highly effective at removing rust, even from complex geometries and hard-to-reach areas. Unlike traditional methods, which may require scrubbing or abrasive techniques, laser rust removers can clean surfaces without leaving residue or damaging the underlying material.

- Environmentally Friendly: One of the most significant advantages of laser rust removal is its environmentally friendly nature. The process does not require chemicals or abrasive materials, eliminating hazardous waste disposal issues and reducing the carbon footprint associated with rust removal.

- Cost Efficiency: While the initial investment in laser rust removal equipment may be higher than traditional methods, the long-term cost savings are substantial. Laser cleaning requires less labor, reduces downtime for equipment maintenance, and minimizes the need for consumables, leading to lower operational costs over time.

- Precision and Safety: Laser rust removers allow for precise cleaning, reducing the risk of damaging the substrate. This precision is particularly important in applications involving delicate or high-value components. Additionally, by eliminating the need for hazardous chemicals, laser cleaning enhances workplace safety.

- Versatility: Laser rust removers can be used on various metals, including steel, aluminum, and alloys. This versatility makes them suitable for a wide range of applications, from automotive and aerospace to manufacturing and maintenance.

3. Applications Across Industries

Laser rust removers are widely used across numerous industries due to their effectiveness and versatility. In the automotive sector, they are employed to clean rusted car frames, components, and engines. In aerospace, laser cleaning is critical for maintaining aircraft parts, ensuring safety and performance by preventing corrosion.

Manufacturing industries use laser rust removal for preparing surfaces for welding, painting, or coating, ensuring better adhesion and quality. Additionally, laser cleaning is utilized in the maintenance of infrastructure, such as bridges and pipelines, where rust removal is essential for structural integrity.

4. Comparative Analysis with Traditional Methods

When evaluating the effectiveness of laser rust removers, it’s essential to consider them against traditional rust removal methods such as sandblasting, chemical treatments, and mechanical grinding. Each method has its strengths, but they also come with significant drawbacks:

- Sandblasting: This method involves propelling abrasive materials at high speeds to remove rust. While effective, sandblasting can create a lot of dust, generate hazardous waste, and damage the underlying metal, especially if not performed carefully. It also requires extensive cleanup afterward, making it time-consuming and labor-intensive.

- Chemical Treatments: Chemical rust removers are often effective but can pose significant health and environmental risks. Many chemicals used in these processes are toxic, requiring stringent safety measures and disposal protocols. Additionally, the residues left behind can lead to further corrosion if not thoroughly rinsed and neutralized.

- Mechanical Grinding: While grinding can effectively remove rust, it can also remove material from the substrate, leading to reduced structural integrity over time. This method is labor-intensive and can create heat that warps or damages sensitive components.

In contrast, laser rust removers provide a cleaner, faster, and safer alternative. They eliminate the risks associated with abrasive techniques and hazardous chemicals while preserving the integrity of the underlying materials. This makes laser cleaning a superior choice for many applications, particularly in industries where component integrity is critical.

Conclusion

In conclusion, laser rust removers represent a cutting-edge solution for effectively addressing rust and corrosion in industrial applications. Their operational efficiency, environmental benefits, cost-effectiveness, precision, and versatility position them as essential tools for modern maintenance practices. As industries continue to prioritize sustainability and operational efficiency, the adoption of laser rust removal technology is likely to expand, leading to cleaner, safer, and more efficient industrial processes. By integrating laser rust removers into their operations, businesses can not only enhance their maintenance capabilities but also contribute to a more sustainable future.